Tel:15810058385;

Current:Home >> Technology

Author: 江苏万呈机械有限公司 time:2019/10/24Views:1374

Fabrication of marine electrical prefabricated parts and cable penetration blocking technology

Technology of communication & sealingforsteelship

Fireproof and watertight sealing

Using of plasticine, thermoshrinktube

The cable pipe in the cabin shall be sealed with rubber mud; the cable pipe and stuffing box in the engine room and open deck shall be sealed with heat shrinkable sleeve, and the stuffing box on the electrical box in the living area shall not be sealed generally. The construction process of heat shrinkable casing shall refer to the manufacturer's standard requirements as follows:

Cablepipe in China to be sealedwithplicine; cablepipe and cablelanding in Europe and open decks to be sealedwither malshrinktube, the cablelandsonelectively combined with seacinacommodation areagenerally. Technology of the malshrinktubeshould be accordingtomaker's standard.

1.3 Manual of thermal shrink tube

(1) select the heat shrinkable sleeve of appropriate specification according to the above table. Generally, the inner diameter of the selected heat shrinkable tube after shrinkage shall be more than 1mm less than the outer diameter of the cable, and the length of the heat shrinkable tube shall be more than 5-10% of the length to be covered.

Select the therma shinktubeaccording about table, the dimension of the therma shinktubeshould be smaller 1 mm than cable outlet metric, length of the therma shinktubeshould be longer 5-10% than the coverage length.

(2) mark both ends of the cable to be covered, and use a clean rag to remove dust and dirt.

Market the cable before seal, outer heath of cable should be led.

(3) if necessary, a layer of hot-melt adhesive tape (about 0.3mm thick) can be evenly wound on the preheated cable part, and the hot-melt adhesive tape shall be pressed tightly.

Preheating the outer heath of cable, the wrapon layer her malmeltta petightly (thicknessabout 0.3mm) if necessary

(4) set the heat shrinkable sleeve, heat it from the middle of the heat shrinkable sleeve along the circular direction with a plastic welding gun or a blowtorch after positioning, and then heat it from the middle to one end gradually to the complete contraction. The hot melt glue overflows at the port. After one end shrinks completely, heat the other end in the same way. Pay attention to move along the circular direction when heating, and expand outwards after the complete contraction. To avoid wrinkles and bubbles.

After fitting the thermal shrinktube, use the blowtorchtoheat.headingemiddler of the thermal shrinktubeatfirst, when they are in kuniformly, the waiting from middletooneand, after the thermal melttapeextravasation and shrinkfull, the other one is in the same way. The cableandtubeshouldbemoveau around during the heating to avoid rule leading bundle.

(5) after shrinking the heat shrinkable sleeve, heat it again to make the surface smooth and flat. The plastic welding gun shall be moved quickly during the whole heating process.

Reheating once again after finishing fully, during the whole process, please remove the blowtorch quickly to keep the surface utility and to avoid temperature to high.

(6) if the size difference is too large or there is a sharp angle transition at the connection of the big and small ends, shrink the heat shrinkable tube with the smaller size at one end of the small end first with the method of Clause (5), and then put on another heat shrinkable tube. Or wrap it with hot melt adhesive to make it smooth and transition, and then cover the heat pipe.

Forthereducer, if dimension discrepancyistoool against here is a cultural core transition, fitted one small dimension tubeorthermalmeltetape on the small endfirst, the nuset the big size the large shrinkbubecover the whole part.

(7) if there is a bend, the heat shrinkable pipe shall be heated from the bend to make it fully shrink before expanding to both sides.

I here is a benedictor, its house being the mental shrinkbubefrom the Benedicts, the next to both sides.

(8) the next operation can be carried out after the heat shrinkable pipe is completely cooled, and the cooling time is better to be more than 15 minutes.

After all, it can be done next operation; its letter the cooling time over 15 minutes.

2. Sealing technical for fire-resistant cable frame (barrel)

2.1 preparation

2.1.1 check whether the factory certificate of main materials is complete

Check therelativecertificateofthe materials.

2.1.2 if there is any doubt about the quality of the stored or incoming materials, small sample inspection can be carried out. Take a small amount of filler samples, mix and mix components a and B according to the specified proportion. If the product does not solidify within one day, it will be invalid.

If you double the quality of the stuff, please take the example, accordingsupport, mixparta and PartB, ifitcannot solidify inounday, it is most beneficial.

2.1.3 according to the relevant drawings, the cables inside the penetration shall be laid completely, straightened and kept clean.

Finished the cable layout according to the drawings, keepstraight and cleaning.

2.2 construction of pd100 plugging material

2.2.1 to fill the liquid plugging material, first fill the two ends of the fire-proof cable frame or the lower end of the fire-proof cable drum with the expansion plugging material before pouring the sealingslurry, please give it the expansion caulking the end of the penetration.

2.2.2 fill the gap between each cable and the inner wall of the penetration with the expansion plug. The large gap can be overlapped and blocked. The plug should be level with the end face of the penetration. The comb face must be placed inward. Then spray the expansion promoting liquid on the expansion plug. After about 30 minutes, the opening can be blocked and the sealing filler can be filled.

Being under the construction, putpd100caulking the space, we can afford to be able to transfer, the praying expanding liquid to the examining, the caulking stars and after 30minutes, the space can be fully locked, the nitis possibletoour the seaming lurry.

2.3 using way of the DMT sealing

2.3.1 packing preparation

The formula of the filler includes two components a and B. component A is powder and component B is powder.

Stuffing box

Hatch cover

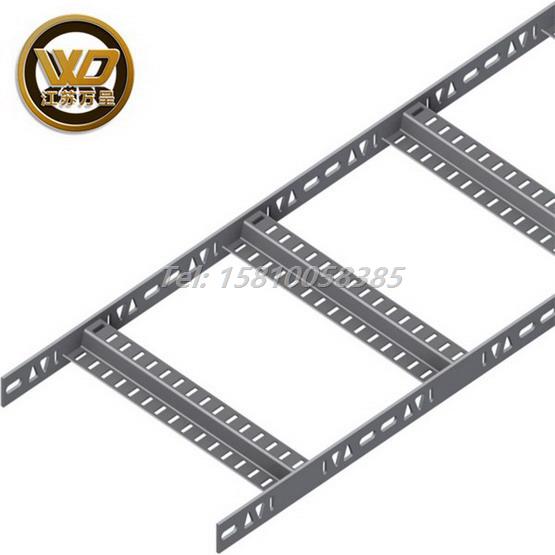

Cable tray

Cable tray

Cable tray

Cable tray

Qr code

友情链接:

服务热线

15810058385;

扫一扫,关注我们